In the field of pipe welding, electro fusion machines have become indispensable tools for ensuring secure and reliable connections. These machines are particularly popular for joining polyethylene (PE) pipes, which are widely used in various industries, including water supply, gas distribution, and sewage systems. Understanding the cost of an electro fusion machine and its components, such as the electro fusion welding machine, is crucial for businesses and contractors who need to invest in reliable and efficient equipment. In this article, we will delve into the factors that influence the cost of electro fusion machines, provide an overview of the electro fusion welding machine, and highlight why JS PIPE is a trusted brand for these essential tools.

Understanding Electro Fusion Machines

An electro fusion machine is designed to weld PE pipes and fittings using an electrical current. The machine works by generating heat through the electrical resistance of a specially designed fitting. This heat causes the pipe and fitting to melt and fuse together, forming a strong and leak-proof joint. Electro fusion welding is highly regarded for its precision, reliability, and ability to create durable joints without the need for additional materials.

Key Factors Influencing the Cost of Electro Fusion Machines

- Machine Type and Specifications: The cost of an electro fusion machine varies depending on its type and specifications. Basic models designed for smaller diameter pipes are generally less expensive than advanced models capable of handling larger pipes and complex welding tasks. Features such as automatic operation, data logging, and compatibility with various pipe sizes can also influence the price.

- Brand and Quality: The reputation and quality of the brand significantly impact the cost. Established brands like JS PIPE are known for their high-quality products, which may come at a premium price. However, investing in a reputable brand ensures reliability, durability, and access to customer support and service.

- Accessories and Components: The cost of an electro fusion machine can also be influenced by the included accessories and components. Machines that come with additional fittings, cables, and welding tools may have a higher upfront cost but provide better value in the long run.

- Technological Advancements: Machines with advanced technological features such as digital displays, automatic voltage adjustment, and data logging capabilities tend to be more expensive. These features enhance the machine’s performance, ease of use, and ability to ensure consistent weld quality.

- Market Demand and Availability: The cost of electro fusion machines can fluctuate based on market demand and availability. Prices may vary regionally, and temporary shortages or increased demand in certain industries can lead to price adjustments.

Overview of Electro Fusion Welding Machine

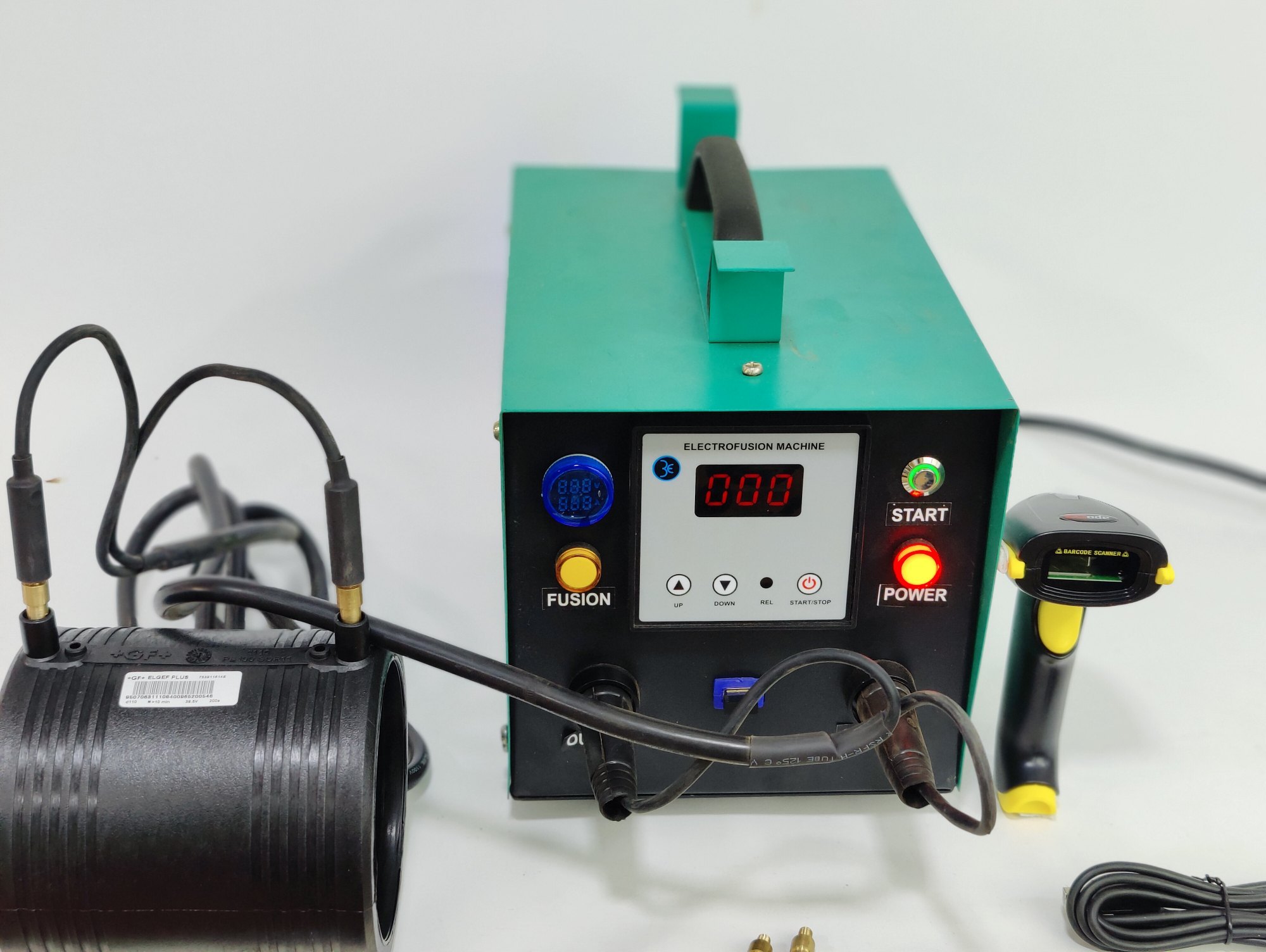

An electro fusion welding machine is a specialized tool designed for the electro fusion process. These machines are equipped with features that ensure precise control of the welding parameters, including temperature, time, and pressure. The key components of an electro fusion welding machine include:

- Control Unit: The control unit manages the welding process, ensuring that the correct voltage and current are applied for the appropriate duration. Advanced control units may have digital interfaces and programmable settings for different pipe and fitting sizes.

- Cables and Connectors: These components connect the machine to the electro fusion fittings, allowing the electrical current to flow and generate the necessary heat for welding.

- Cooling System: Some machines are equipped with cooling systems to manage the heat generated during the welding process, ensuring that the machine operates efficiently and safely.

- Safety Features: Modern electro fusion welding machines are designed with safety features such as overcurrent protection, overheating sensors, and automatic shut-off mechanisms to prevent accidents and ensure user safety.

Why Choose JS PIPE for Electro Fusion Machines?

JS PIPE is a leading brand in the pipe welding industry, known for its high-quality electro fusion machines and accessories. Here’s why JS PIPE stands out:

- Reliable Performance: JS PIPE electro fusion machines are designed for reliable and consistent performance, ensuring strong and durable welds every time.

- Advanced Technology: JS PIPE incorporates the latest technological advancements in their machines, offering features such as digital controls, data logging, and automatic voltage adjustment.

- Comprehensive Support: JS PIPE provides excellent customer support, including guidance on machine selection, installation, and maintenance. Their team of experts is always ready to assist with any questions or concerns.

- Quality Assurance: All JS PIPE products undergo rigorous quality control processes to ensure they meet the highest standards of performance and durability.

Conclusion

The cost of an electro fusion machine varies based on several factors, including type, brand, features, and market conditions. Electro fusion welding machines are essential tools for creating reliable and leak-proof joints in PE pipes. Investing in a high-quality machine from a reputable brand like JS PIPE ensures reliable performance, advanced technology, and excellent customer support. By choosing JS PIPE for your electro fusion needs, you can achieve strong and durable pipe connections, enhancing the efficiency and reliability of your piping systems.

Keep an eye for more news & updates on Mystorieslist!